44 years of cultivation broaching machine Field

Inherited in the original Changsha machine tool factory, professional broaching equipment manufacturers

3generation inheritance

Three generations only want to do one thing well and focus on the innovation and improvement of broaching process.

60 national patents

13 patents for invention

300 Service for well-known enterprises

Focus on broaching process innovation to enhance

5The main drafting unit of the national industry standard.

As the main drafting unit, our company participated in the customization of a number of national standards.

About Sisheng

Changsha Sisheng Intelligent Equipment Co., Ltd. is a high-tech enterprise specializing in the research and manufacturing of lathes. The enterprise is inherited from Changsha Machine Tool Plant, one of the "Eighteen Arhat", which has rich technical background and three generations of people engaged in the research, development and manufacturing of broaching machines. The lathe products designed by the company have been widely used by many well-known enterprises such as FAW, Dongfeng, BYD, ZF, Sany, XCMG, Shuanghuan, AUTOLIV, and are also exported to countries such as Romania, Mexico, and Brazil.

State-level "specialized and sophisticated enterprises" small giant enterprises

Hunan Enterprise Technology Center

Hunan manufacturing industry single champion-CNC pulling machine

National standard-setting unit for metal-cutting machine tools

Service Items

Continued years of production experience, focusing on the production and manufacturing of product quality

01

Broaching automation

02

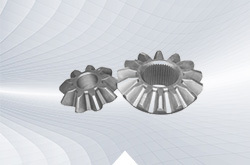

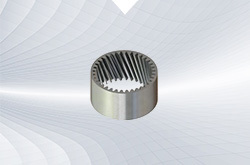

Internal tooth machining

03

Internal helical tooth machining

04

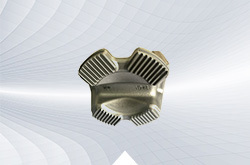

Plane tooth profile machining

05

External tooth machining

06

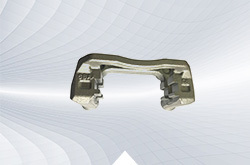

Profiled piece broaching

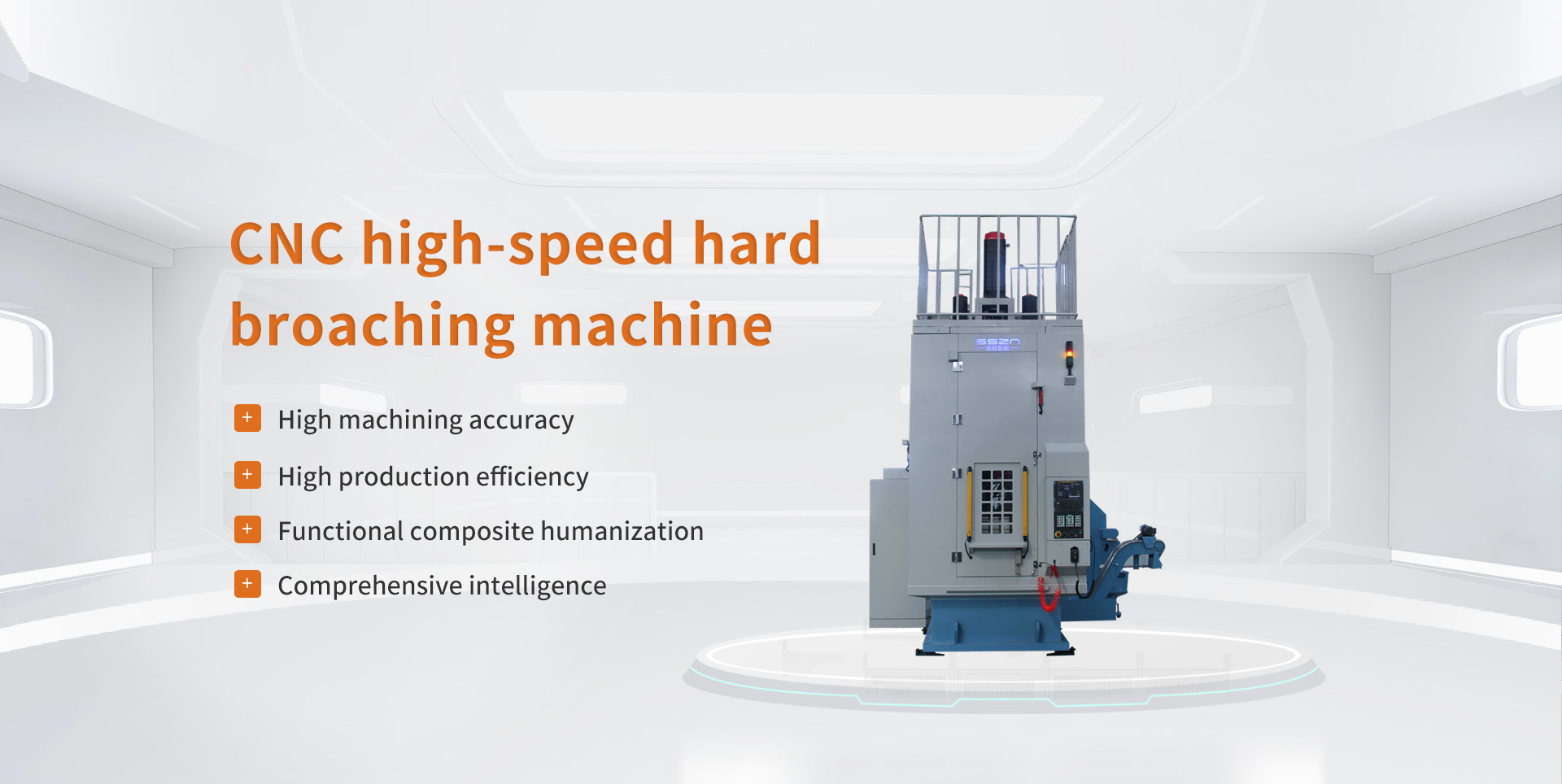

Servo broaching machine

Servo drive, small footprint, high precision, high efficiency, easy maintenance, green environmental protection, energy saving and consumption reduction.

Hydraulic broaching machine

Adopt hydraulic drive, servo hydraulic system, stepless speed regulation.

Special-purpose broaching machine

Through the replacement of tooling, tool guide device and tool, to achieve the specifications of the keyway processing, digital control to ensure that the tool position and feed precise control. The machining process is high-speed broaching and return, which effectively improves the production efficiency of parts.

Horizontal Broaching Machine

Adopt hydraulic drive, stepless speed regulation.

Products

Products

servo broaching machine

Servo drive, small footprint, high precision, high efficiency, easy maintenance, green environmental protection, energy saving and consumption reduction.

hydraulic broaching machine

Adopt hydraulic drive, servo hydraulic system, stepless speed regulation.

Special-purpose broaching machine

Through the replacement of tooling, tool guide device and tool, to achieve the specifications of the keyway processing, digital control to ensure that the tool position and feed precise control. The machining process is high-speed broaching and return, which effectively improves the production efficiency of parts.

Horizontal broaching machine

Adopt hydraulic drive, stepless speed regulation.

Tenon and groove pulper

Technical Advantages

Partners

Careful service and win-win cooperation

It is our aim to ensure high-quality service in the whole process of pre-sale, in-sale and after-sale.

24 hours online service and engineer overseas service after-sales guarantee

Perfect after-sales service system has covered more than 100 countries around the world.

News Center

2023/10/23

The development of the industry in the world

2023/08/04

Common Faults of Horizontal Internal Broaching Machine Corresponding Solution Sharing